Product Description

Bioengineering unleashed

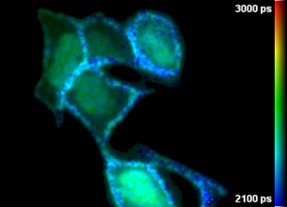

The Alveole Primo system provides micropatterning, hydrogel polymerization and microfabrication, all in a single device. It is designed to create bespoke in vitro cellular microenvironments and get better cell models for your cell biology experiments or cryo-ET studies.

PRIMO 2 is new generation hardware with compact footprint, new optical design allowing epi-fluorescence microscopy and faster performance.

Developed by Alvéole scientists after the LIMAP* technology (Strale P.O. et al, Adv Mater. 2016), the PRIMO maskless photopatterning system (DMD based) can engineer custom in vitro cell microenvironments through three techniques: micropatterning, hydrogel structuration and microfabrication.

PRIMO bioengineering technology

Developed by Alvéole scientists after the LIMAP* technology (Strale P.O. et al, Adv Mater. 2016), the PRIMO maskless photopatterning system (DMD based) can engineer custom in vitro cell microenvironments through three techniques: micropatterning, hydrogel structuration and microfabrication.

PRIMO workflow for better in vitro cell models:

- SUBSTRATE selection and preparation

- PATTERN DESIGN and upload in Leonardo software

- UV PROJECTION BY PRIMO for micropatterning, microfabrication, hydrogel polymerization

- USING CUSTOM in vitro CONDITIONS